This is where VIAIR comes in with their completely sealed, oil-less C-class air compressors. Being completely sealed means that they can be mounted anywhere, including outside of the car where it is subjected to dust and moisture; their oil-less construction means they can be mounted in any orientation (though VIAIR recommends they be mounted in its normal upright position - side-mounting may cause the piston seal to wear out faster as the weight of gravity may cause an issue; and mounting upside down may reduce the efficiency of heat dissipation as the heat will want to travel upwards into the motor housing as opposed to the cooling fins). A few other things to note about the VIAIR compressors are:

- They do not require running in - just plug-in, check for leaks and away you go.

- They do not come with a pressure switch - one must install the compressor with a relay and pressure switch to ensure the compressor does not exceed its max working pressure (and if it does, compressor failure may occur).

- They are equipped with thermal overload protectors to prevent it from overheating and damaging any components.

Now, before I go into comparing the different VIAIR compressors available, I'll explain over some important specs. First of all, air compressors pump air into a tank through a leader line. Common fittings are 1/4" and 3/8" NPT. Obviously the larger leader line should be able to pump air in more efficiently, and the size of the line determines what water traps you can use. Otherwise I don't think there's of any other significance. Next, air compressors are made to be able to pump in a maximum working pressure (MWP). This is a measure of how pressurised the air in the tank can reach before the compressor runs out of puff. The higher the MWP, the stronger the compressor is (capable of having the tank store more pressurised air, thus more air in reserve). The max pressure most airbags can contain I believe is up to 140 PSI (and they're rarely set that high up) so a compressor with an MWP of 140 PSI is sufficient for use in an air suspension system. Scroll down towards the end of the article for a more in-depth view in this. Next is the duty cycle (DC). Expressed as a percentage of an hour, it explains how long the compressor can run at a specific pressure. A duty cycle of 100% @ 100 PSI means that the compressor can run non-stop if the tank is constantly at 100 PSI (i.e. the air is continually being released out as the compressor pumps in the air). Then we have the maximum amp draw (MAD). This is the maximum electrical load that the compressor demands when it is running at its full capacity. The higher the MAD, the harder the compressor is run. This usually means a faster fill rate and hotter running temperatures. Finally there's the fill rate (FR). This is essentially the time it takes for the compressor to pump air into a certain tank up to a certain pressure, e.g. a 5 gallon tank up to 145 PSI.

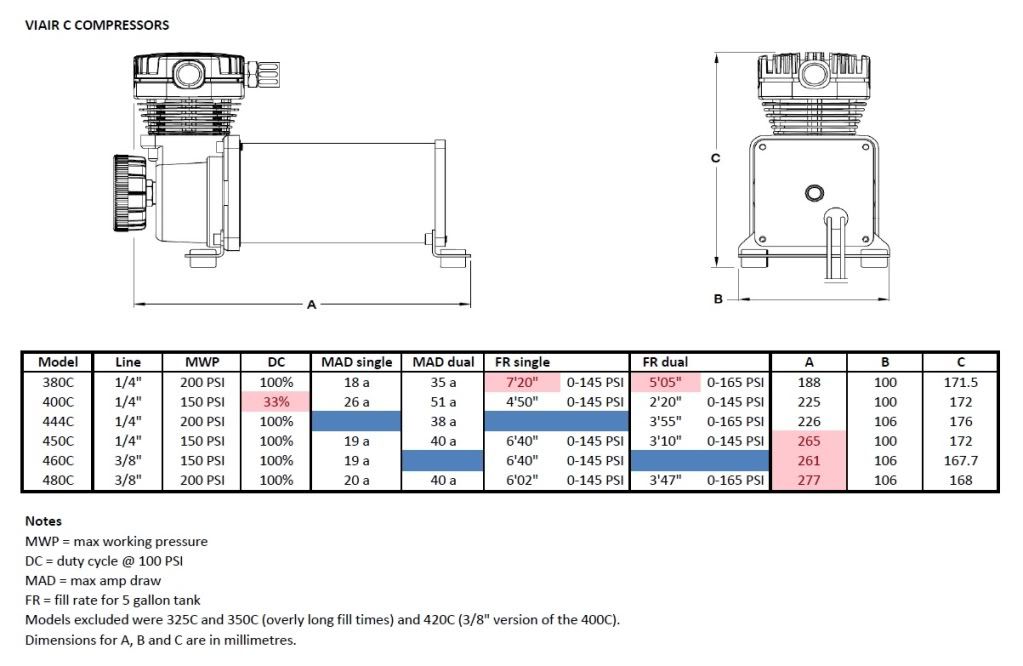

So keeping all that in mind, here is a fairly extensive comparison I did (over a day at work :D) between the 300 and 400 series C-class compressors (click for a readable size):

All the specs were taken from VIAIR's website. The blank spaces are there as I couldn't find the specs for them, and I highlighted specs that I found undesirable in what I'm looking for in a compressor (or two).

I'll attempt to summarise my findings. Based on those specs (and going off from user feedback I've found on various forums):

- Fastest compressor is the 400C, because it runs a more demanding motor (hence the high MAD and short DC). It's also the loudest.

- The smallest (and slowest) compressor is the 380C.

- There's no huge difference between the 450C, 460C and 480C except the 480C has a 3/8" line and has a MWP of 200 PSI (I don't really have a preference for either - 200 PSI is nice but 150 PSI will still do fine IMO).

- 444C seems to be the best of both worlds - small in size but "reliable". 200 PSI MWP is a bonus.

- Cost goes up as you move up the model line (no major differences though)

AZ OB2

Line: 1/2" NPT

MWP: 200 PSI

DC: 100% @ 200 PSI (not 100 PSI!)

MAD single: 35 a

MAD dual: 70 a

FR single: 3'31" (0-150 PSI)

FR dual: 2'05" (0-170 PSI)

Length: 320.5 mm

Width: 140 mm

Height: 206.1 mm

It's simply a much larger unit capable of higher outputs. Its fill rate with one compressor is comparable to that of a dual 480C setup, and as such, many retailers include a single OB2 or a dual 480C in their top-end kits. There is a huge difference in pricing though - a single OB2 is comparable to that of a dual 480C kit. All forum threads I've seen state that a single OB2 is more expensive than dual 480Cs, but trawling through eBay is showing up the opposite, with dual 480Cs being around $400USD before shipping, and an OB2 around $350USD before shipping.

Single vs Dual

Almost always, two units are better than one but I'll just go through it all briefly. If comparing a single and dual setup comprising of the same compressors, then obviously having a dual setup reduces fill time as a consequence of more air being pumped into the tank. As a result, the compressors run for a shorter period which in turn puts less load on them and the heat generation is reduced. Also, if one was to fail, then you still have one more compressor to get you by until you can get it all sorted. Ultimately a dual setup would provide for a very reliable system. The only downside is the cost and having to sacrifice space. I don't think it gets much noiser, but it runs for a shorter time so it doesn't drone for long.

Since I introduced the AZ OB2, it would be interesting to compare using a single compressor versus a dual setup, especially since a single OB2 can pretty much go up against dual 480Cs. Although there's only one OB2, it would still run as efficiently as dual 480Cs. If anything, it'll be faster than the dual 480Cs (see specs above). If I purchase from eBay, it'd be cheaper to get a single OB2 as shipping would be cheaper. The OB2 is a much larger unit, but it's still smaller than two compressors. Only problem though is the reliability side of things - if the OB2 was to fail, then there is no back-up compressor. But then again, if funds allow, a second OB2 could be invested and easily plumbed in to the existing setup provided the tank has provisions for a second 1/2" port (which most purpose-built tanks should have). That'd be awesome...

Amp draw

Running two OB2s that require a max of 70 amperes made me realise that I should cover this issue. Driving a hatchback means almost everything related to it is small and that includes the alternator. An A3/Mk4 running the engine, accessories, two OB2 compressors pumping air @ 100 PSI and blasting the stereo system would be a massive ask for the stock alternator. If I wanted to run dual OB2s and decent ICE later on down the track, I think I will have to uprate the alternator to a heavy duty unit and use a more appropriate battery. I've thought about running two batteries but that will be another blog article I'll cover later on.

I guess what I'm trying to say is that when choosing compressors, it's not just a simple matter of cost vs fill rate; you gotta think about reliability too and not just the compressors, but with the rest of the car too.

MWP and using pressure switches

Pressure switches are a necessity in any air compressor setup so as to not overwork the compressor to pump pressures over its MWP rating. Doing so will reduce the life of the working components of the compressor as it forces it to pump in air at pressures it's not meant to do. So essentially, the pressure switches are put in place to kill the compressor once the tank reaches the set pressure. These pressure switches also tell the compressor to turn back on once the tank reaches a certain lower pressure. For example, 200 PSI pressure switches may have a cut-off (or should that be a cut-on?) at 165 PSI. This means that at 200 PSI, the compressor will turn off and once the tank reaches below 165 PSI, it'll turn it back on again.

Sound deadening

For me, I don't want to sacrifice comfort when installing and using air suspension. After all, I'm flicking switches so I can ride comfortable and without scraping everywhere, so sound deadening is an important topic to cover for me.

The best and easiest way to reduce the noise made by the compressors are to dampen the feet in which the compressor is mounted. Mounting a compressor on rubber feet makes a huge difference if compared with hard-mounting a compressor on the chassis. It's all to do with resonance - sound waves are dispersed through vibrating air molecules; a piece of metal resonating from a mounted, active compressor will make a fuckload of noise.

Sound deadener materials lined over the immediate area of where the compressor is mounted will work too. Products like Dynamat, however, adds weight to the area. This reduces physical vibration, decreasing resonance. It doesn't actually stop the sound waves though - a material that "combines a thick foam decoupler with a polymer barrier" is what you want to use. An example is Vcomp. Combining Vcomp with something like Dynamat would produce the best results (I would assume you lay the Dynamat first, then the Vcomp, since Dynamat is supposed to affect the material it's attaching to and the Vcomp acts on the sound waves).

Any barrier in between the compressor and the cabin of the car will also reduce the noise. Mounting a compressor under a false floor will definitely reduce noise, and sound deadening the false floor will further dampen the sound. Some guys have even gone so far as to house individual compressors, and installing a computer fan for ventilation and cooling. This, combined with pretty much all the above combos will dampen the sound so much that it's barely audible if music is on.

Wiring in dual compressors

Came across this link and thought it'll come in handy later ;) http://bagriders.com/modlab/tech/dualc_wd.pdf

I think that's all for now, I'll add a few more things to this (like pictures!) as I am informed!

Cooper Freer Compressors is one of the experienced suppliers in Leicester, Derby, and Nottingham area. We are supplying quality surplus compressed air solutions at reasonable prices. Purchase used or new air compressors among our broad range of products.

ReplyDelete